181 Shafer Drive

Romeo, MI 48065

PH: 586 331 7253

Fax: 586 331 7256

Services

What We Do

At Express Gage, it is our job to identify and comply with customer requirements. It is our goal to design and produce goods that satisfy and exceed the use intended by our customers. We are continually striving to improve quailty management. Persistant communication about the importance of quality throughout the organization promotes defect free goods for our customers.

Design

At Express Gage, Inc. our engineering capability is supported by Autodesk, Unigraphics and Catia software. To better serve our customers, we can recieve data in any format and at T1 speed. We host our own FTP site and can recieve up to 500 mb files at data@expressgage.com

Express Gage regularly hosts interactive 3D/2D design reviews, or, for non-local customers, electronic design reviews are available.

Production

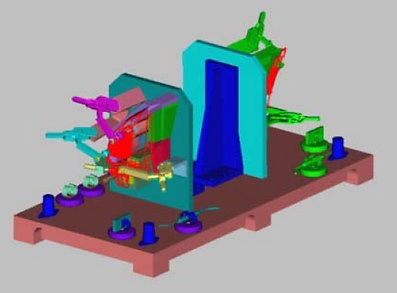

The journeymen builders Express Gage, Inc. employs are highly skilled and are able to provide unsurpassed quality to meet and exceed customer's expectations. We commonly produce CMM holding fixtures and attribute/variable data checking fixtures tailored to any specifications that are required by our customers.

Our dedication and skill allows us to build fixtures/tooling for any application regardless of complexity.

N/C Machining

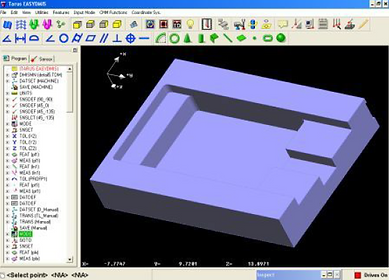

At Express Gage, Inc. our CNC machining capability is supported by Work NC software, with our largest 5-axis machine measuring 10 feet long. With 3D stock management when machining parts, the stock model can be continually updated based on 3D or 3D/2D tool paths. With this, the 3D stock model is updated taking into account any stock removal in undercut areas. These features allow for a world class finish held to any tolerance our customers might require.

CMM Inspection

Express Gage, Inc. has multiple CMM machines capable of verifying tooling, fixtures and parts for use in automotive and aerospace industries. At 21 ft long, the newest machine in the CMM department is capable of checking sizable tools. The Tarus CMM machines carbon fiber composite construction reduces weight and increases accuracy. These precision measuring machines for our global customers are equipped with innovative features and software ideal for inpsection, gage certification, gage R&R studies as well as party layouts and reverse engineering.

With it's unique, customizable, graphics-based operator interface, EZ-DMIS can be tailored to suit specific measurement tasks that range from simple parts to complex, contoured surfaces such as sheet metal assemblies.